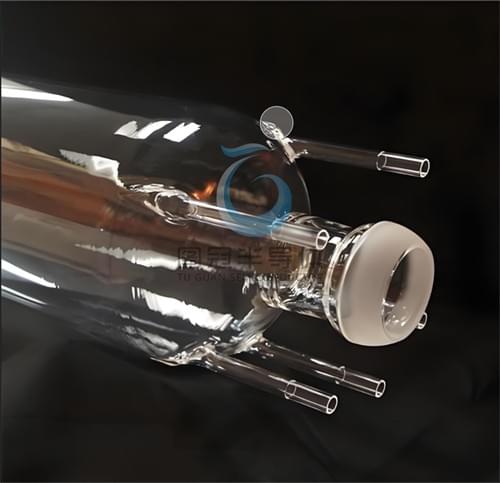

Quartz furnace tube

1. Product Name: High-Purity Quartz Furnace Tube

2. Material Specifications

Primary Material: Fused quartz (SiO₂ ≥ 99.9%)

Density: 2.2 g/cm³

Thermal Stability: Resists thermal shock up to 1200°C (continuous use).

3. Dimensions

Parameter : Value / Tolerance

Outer Diameter : 415 mm / ±1.5 mm

Inner Diameter : 405 mm / ±1.0 mm

Wall Thickness : 5 mm / ±0.5 mm

Length : 2300 mm / ±5 mm

4. Technical Parameters

Max Working Temperature: 1200°C (short-term peak: 1450°C).

Pressure Resistance: Withstands 1 atm (vacuum or low-pressure environments).

Thermal Expansion Coefficient: 0.55 × 10⁻⁶ /°C (20–1000°C).

Surface Finish: Smooth, non-porous, acid-washed.

5. Key Features

① Ultra-high purity for contamination-sensitive processes.

② Excellent chemical resistance to acids, halogens, and most corrosive gases.

③ Low thermal expansion ensures dimensional stability.

6. Applications

Semiconductor wafer processing.

High-temperature annealing, CVD, or diffusion furnaces.

Laboratory research and optical industries.

7. Handling & Storage

Packaging: Foam-padded wooden crate.

Storage: Keep dry, avoid direct sunlight, and store horizontally.

8. Notes

Avoid mechanical impact or rapid temperature changes (>200°C/min).

Custom modifications (e.g., flanges, coatings) available upon request.

For detailed technical support or bulk orders, please consult our engineering team.

Email:luzhenzhu@tuguanshiying.com