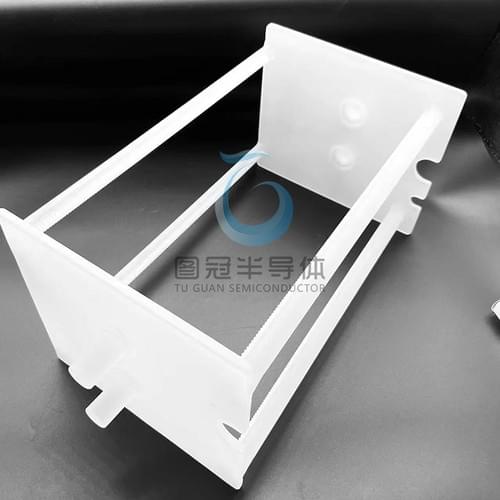

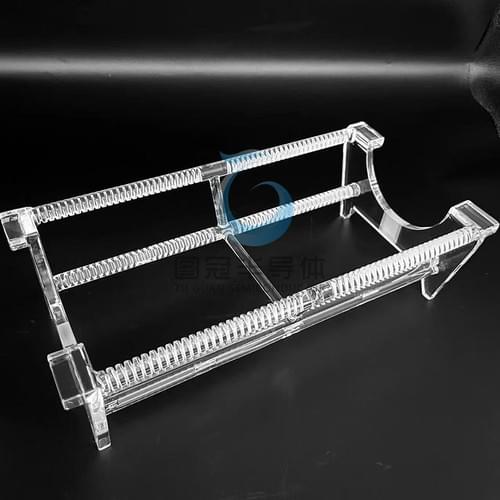

Quartz boat

1. Product Overview

The Quartz Cleaning Boat is a high-purity, corrosion-resistant carrier designed for semiconductor, photovoltaic, and precision electronics industries. It is used to hold wafers or components during wet/dry cleaning, acid etching, or high-temperature processes.

2. Technical Specifications

Parameter : Details

Material : Fused Quartz (SiO₂ ≥99.99%)

Dimensions : Customizable (Standard: Length 200–500 mm, Width 50–150 mm, Height 20–50 mm)

Max. Temperature : 1,200°C (Continuous Use) / 1,450°C (Short-Term)

Surface Finish : Acid-polished, Ra ≤0.8 μm

Purity : Low metallic impurities (Na, K, Fe, etc. <1 ppm)

Thermal Stability : Coefficient of Thermal Expansion (CTE): 0.55 ×10⁻⁶/°C (20–1,000°C)

3. Key Features

High Chemical Resistance: Resists HF, HCl, HNO₃, and other aggressive chemicals.

Low Thermal Expansion: Minimizes deformation under rapid temperature changes.

Non-Contaminating: Ultra-clean surface prevents particle adhesion.

Custom Design: Slot spacing, depth, and boat geometry tailored to client needs.

4. Applications

Wafer cleaning in wet benches (RCA, SC1/SC2).

Acid bath processes (e.g., BOE etching).

High-temperature annealing/diffusion steps.

CVD/PVD chamber component handling.

5. Quality Assurance

Compliance: Meets SEMI F20/F47 standards.

Testing:

ICP-MS for impurity analysis.

Surface roughness measurement via AFM.

Thermal shock testing (1,000°C ⇄ 25°C, 10 cycles).

6. Packaging & Storage

Individually packed in anti-static, ESD-safe containers.

Store in a dry, dust-free environment (10–30°C).

7. Precautions

Avoid mechanical impact or sudden temperature changes (>10°C/min).

Clean with DI water or ethanol before first use.

8. Contact Information

For customization or technical support, contact:

Email: [luzhenzhu@tuguanshiying.com].