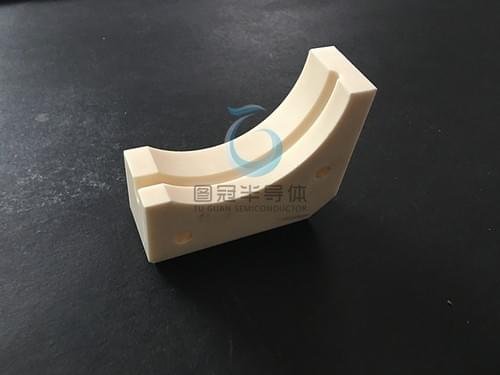

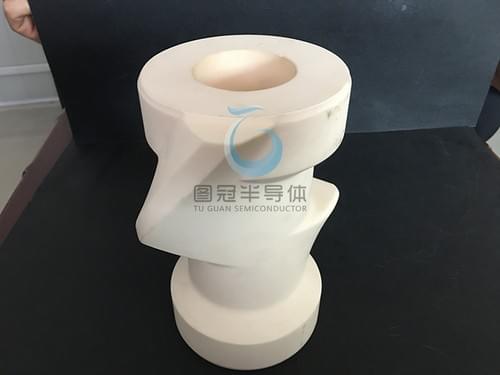

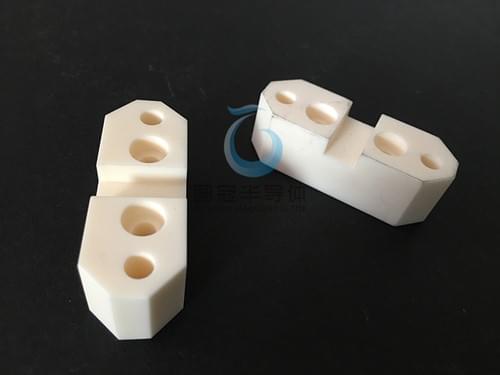

Ceramic block

1. Basic Dimensions

Outer Diameter (OD): 300.0 mm ±0.1

Inner Diameter (ID): 210.0 mm ±0.1

Height (H): 6.35 mm ±0.05

2. Material Properties

Base Material: Al₂O₃ (Alumina Ceramic) / Optional: ZrO₂, Si₃N₄

Density: ≥3.90 g/cm³

Flexural Strength: ≥350 MPa

Thermal Conductivity: 24-30 W/(m·K)

Dielectric Strength: ≥15 kV/mm

3. Tolerance & Surface Quality

Concentricity: ≤0.05 mm (OD vs. ID)

Parallelism: ≤0.03 mm (Top/Bottom Surfaces)

Surface Roughness: Ra ≤0.4 μm

4. Key Performance Tests

Dimensional Inspection: Per ISO 286-2

Leakage Rate Test: ≤1×10⁻⁹ mbar·L/s (Helium Mass Spectrometry)

Thermal Shock Resistance: ΔT ≥300°C (5 cycles, no cracks)

5. Applications

Semiconductor Processing: Vacuum chambers, Plasma etching components

High-Temperature Environments: ≤1600°C (Material-Dependent)

6. Packaging & Handling

Cleanroom Packaging: Class 100 or better

Anti-Static: ESD-safe containers

Compliance Statement

Meets SEMI F47-0706 (Ceramic Components for Semiconductor Equipment)

Disclaimer

Customization available upon request. Critical parameters marked with “□” require explicit confirmation.

Revision History

Recommendations for Finalization

1.Specify exact material grade if available (e.g., Al₂O₃ 99.6%).

2.Add certification requirements (ISO 9001/14001, RoHS, etc.).

3.Include drawings with GD&T symbols if required.